Load Cell Flexures 101

A load cell relies on two main metal components: the flexure and the strain gage. A flexure is a specially designed component that can bend under a load without breaking. They are used in sensors where precise, frictionless movement is needed, like measuring force.

A load cell relies on two main metal components: the flexure and the strain gage. A flexure is a specially designed component that can bend under a load without breaking. They are used in sensors where precise, frictionless movement is needed, like measuring force.

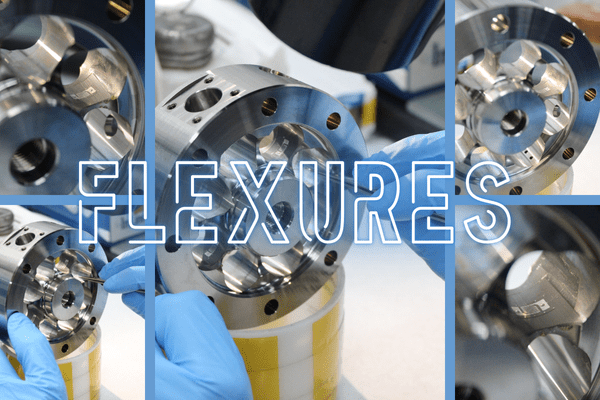

The flexure, a complex machined part, acts as the spring element. They’re also sometimes called “living hinges” due to their ability to provide precise movement. The strain gage, the load cell sensor, measures the flexure’s deflection.

The flexure is at the heart of how a load cell functions:

- It supports the load being measured.

- As the load is applied, the flexure bends, and this deflection is what the strain gage detects.

- Flexures come in various shapes and sizes to suit different load cell applications.

Materials and Manufacturing of Flexures

Interface designs all of our load cell flexures. With thousands of models, capacities, and configurations, manufacturing our flexures is paramount to our load cell accuracy, quality, and precision performance.

Several metals are used for flexures in Interface load cells, including aircraft-quality alloy steel, stainless steel, and high-strength fatigue-resistant aluminum alloy. Flexures are typically manufactured by experienced machine shops, as are Interface flexures, by milling the metal blank into complex shapes for these high-grade metal stock.

The design of the flexure is crucial for both the performance and durability of the load cell. The flexure bears the load; therefore, its failure is structural. Since the gage function measures minute deflections electrically, strain gage failure, on the other hand, is typically not structural; a shift in resistance or gage factor notes failure. The relative propensity to first encounter flexure or strain gage fatigue failure depends upon the design of the transducer.

TIP: Read our InterfaceIQ article on LinkedIn What You Need to Know About Flexures and Models

Flexure’s Impact on Load Cell Performance

The thin section of a simple flexure acts like a virtual frictionless bearing with a slight rotational spring constant. This spring constant of the material may need to be considered when calculating the overall response of the load cell.

Flexures are designed to work best under tension or compression loads. If we apply a tensile force (FT) or a compressive force (FC) to the flexure at an angle of its centerline, the vector component will distort the flexure sideways. Although the results may look similar for both cases, they are drastically different.

- In tension, the flexure tends to bend and straighten out, reaching a stable position.

- In compression, the flexure bends away from the force, creating a side force that can cause it to bend further and ultimately fail at a much lower load than it can handle in tension.

For tensile use, the flexure assumes an equilibrium position safely, even under considerable tension. In the compressive case, the flexure’s reaction can be highly destructive, even though the applied force is precisely the same magnitude and along the same line of action as the tensile force.

If the side force becomes too much for the flexure to handle, it will continue to bend and eventually fail. This means that when the flexure is compressed, it will collapse due to bending, and this will happen at a much lower force than can be applied safely in tension.

The field of force measurement has the same constraints as any other discipline: weight, size, cost, accuracy, useful life, rated capacity, extraneous forces, test profile, error specs, temperature, altitude, pressure, corrosive chemicals, etc. Flexure design is a critical aspect of load cell performance in the design and manufacturing of our flexures. This ensures that the flexure is optimized for the specific application and can withstand the expected loads without failure.

Look inside Interface’s most popular load cell, the 1200 Standard Precision Universal LowProfile® Load Cell.

Interface provides extensive details of flexures used for our LowProfiles, Minis, and Calibration-Grade load cells in our Interface Load Cell Field Guide.

Request a Quote from Interface, The World Leader of Force Measurement